What is Pyrolysis

Biomass pyrolysis is the process of degradation of organic compounds at high temperatures (above 400 C) in an inert atmosphere. It is quite challenging to find such conditions. Therefore pyrolysis performs in an atmosphere where there are negligible amounts of Oxygen. Biomass pyrolysis has become an eye-catching process due to the depletion of energy sources and the low yield of raw biomass. At the end of the process, end products like ash, biochar, bio-oil, and syn gases are formed. Moisture content in the feed, Temperature ranges, heating rates, and residence time has a significant effect on the outcome of the process.

Types of Pyrolisis

There are three main types of pyrolysis. They are slow pyrolysis, fast pyrolysis, and Flash pyrolysis.

Slow pyrolysis

The main objective of the slow pyrolysis process is to produce bio charcoal with superior outcomes. By doing so, the quality of the biofuel will automatically decrease. Here the heating rate of the biomass is quite low compared to other types. Hence the residence time will be around 30 minutes.

Fast pyrolysis

In the fast pyrolysis, the production yield of biofuel is much higher than that of slow pyrolysis. Here the process takes place at high heating rates, and the residence time will be around 5 seconds.

Flash pyrolysis

Flash pyrolysis occurs in a very short time period as low as 1 second at very high heating values. The bio-fuel composition of this is very much higher in this process.

Biomass Structure

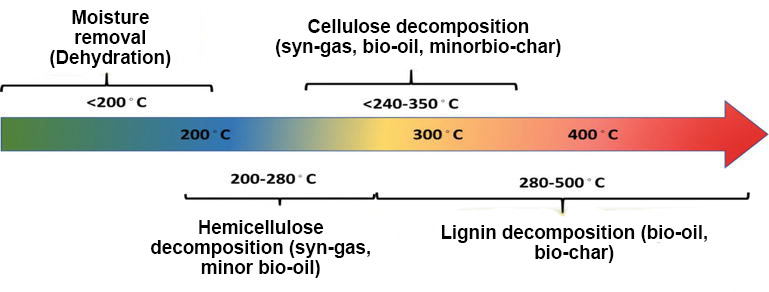

Biomass contains three main macromolecule structures. The pyrolysis process makes sure that these three structures decompose to produce respective outcomes of them. At the temperatures below 200 C, moisture content from biomass escapes and any temperature elevation will result in degradation of biomass structures. Around 200- 300, C Hemicellulose will breakdown to produce syn gases and will start forming bio-oil. At temperatures, around 250-350 Cellulose will breakdown to produce bio-oil, and the formation of biochar will initiate in the same period. At Temperatures around 300 -500, C Lignin breakdown takes place to produce biochar.

Steps in Pyrolisis process

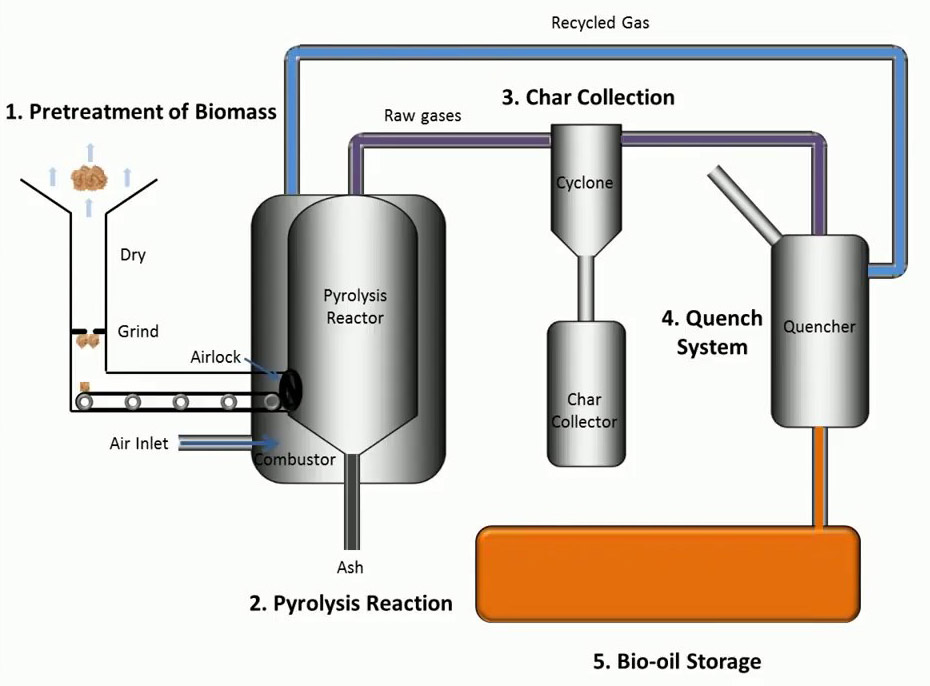

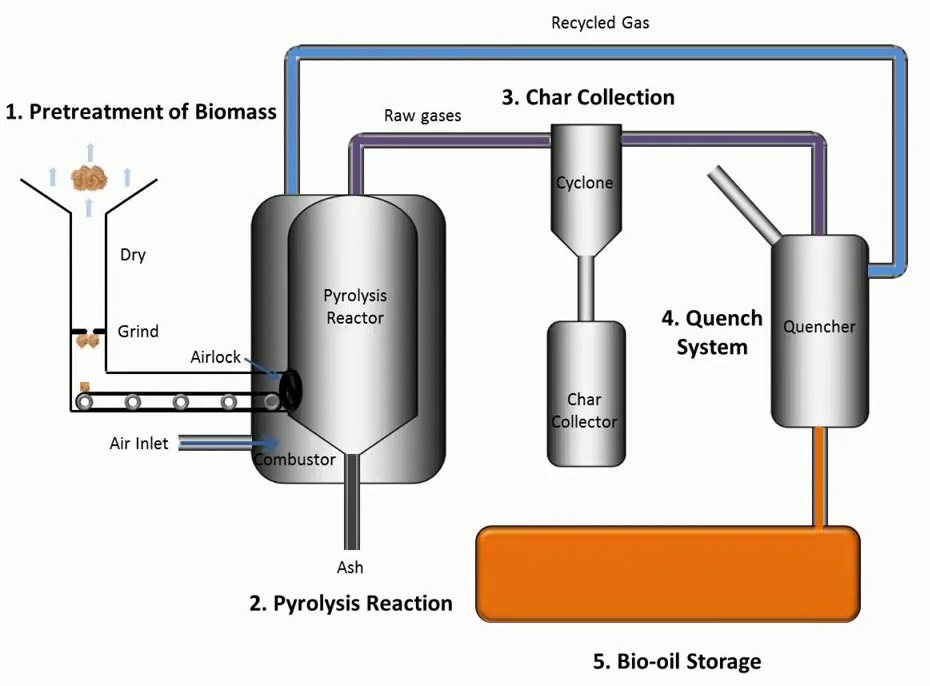

The industrial pyrolysis process includes few steps in forming biochar and biofuel. Initially feed should be prepared in an optimum manner. Pelletized wood particles will have a high contact area, which will promote degradation. Feeding wet biomass will decrease the efficiency of the process. Therefore dry biomass as feed will have higher efficiencies. Pretreated biomass will enter the pyrolysis reactor, which consists of very low levels of Oxygen. Here the heat is supplied by a combustion chamber. As the degradation occurs, decomposed material will leave the reactor to a cyclotron. Here, as the rotation of the gases takes place, biochar will reach the bottom of the cyclotron. After that remaining gas stream along with few liquids will leave from the top to a quencher. Water from a nozzle will feed the quencher to combine the gas stream along with water. This will result in forming bio-oil. Syn gases that weren’t soluble can be recycled back to the combustion chamber.

Types of Reactors

Depending on the purpose, there are a few types of reactors. Fluidized bed reactors, fixed bed reactors, and cyclone reactors are some of the common types.

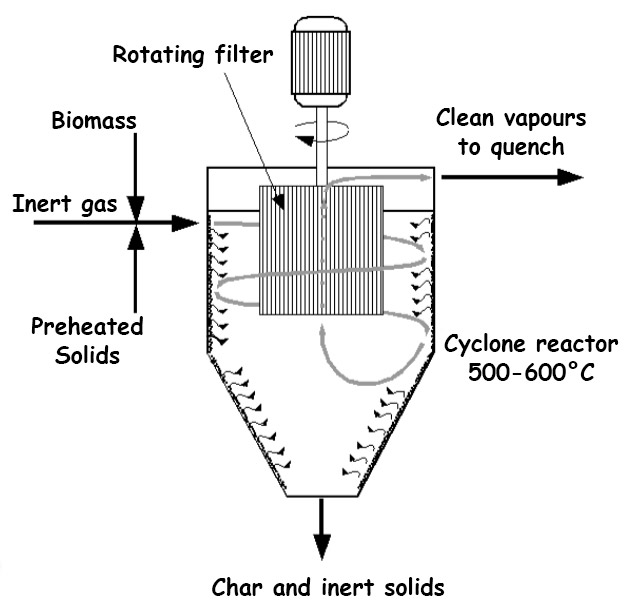

Cyclone reactors

Cyclone reactors have a conical shape. Inert gas enters along the tubes. Biomass will feed to the reactor at elevated forces at the same time. As the reaction takes place, the degraded matter will leave the systems in the form of char, bio-oil, and gases. This reactor suits the fast pyrolysis process.

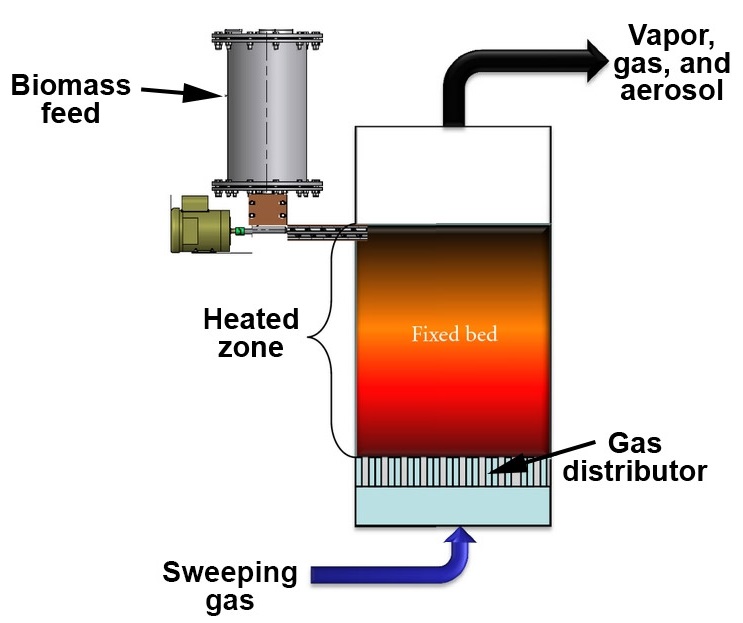

Fixed bed reactors

Fixed bed reactors will suit the slow pyrolysis process. Here the heat for the degradation is supplied from the outside. As the decomposition takes place, the volume of the ingredients increases. Hence the extra amount of gases, as well as bio-oil, will leave the system while biochar retains in the reactor. Here the major outcome is biochar.

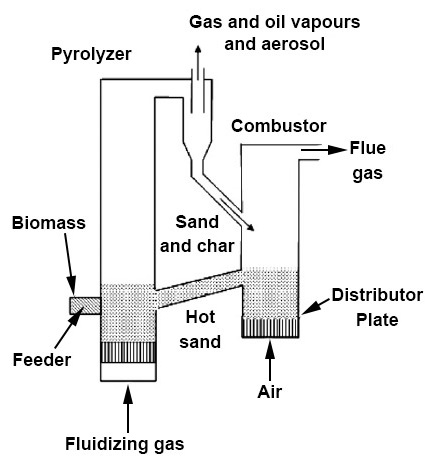

Fluidized bed reactor

A fluidized bed reactor contains a bed with sand. A hot gas airflow enters from the bottom of the reactor while biomass is fed from the top of the reactor. Sandbed allows maintaining the high heating rates in the reactor contributing to fast pyrolysis. In addition to these common types such as vacuum reactors, screw reactors, and plate reactors are there in the industries.

Conclusion

The ability to produce fuel with a high energy density is one of the most common features of pyrolysis. In addition to that, biochar derived from the process will emit very little soot compared to raw biomass. Even solid wastes and plastics can be pyrolyzed. This will provide a considerable boost to waste management, as well. Pyrolysis will surely grow even more given the fact that people are in search for renewable energy sources.

Pingback: Solid Waste Management - Chemical and Process Engineering