Introduction to Boiler Water Treatment

Boilers have become a common and a much-needed component in most of the industries. The primary purpose of a boiler is to produce steam that can efficiently generate heat. Hence extra attention should be given to boiler maintenance. The working pressure of boilers is much higher concerning atmospheric conditions. Therefore feed water to the boiler must be pure as possible. Having untreated water with certain impurities creates huge problems for its operation. Scaling can reduce heat transfer and thereby increasing the cost of fuel. Corrosion in the boiler can create severe damages to the boiler. Replacing the damaged components can be very costly and will hinder the operation of the plant. Therefore a well-organized boiler water treatment program is a must to achieve the most out of a boiler.

Boiler Water Cycle

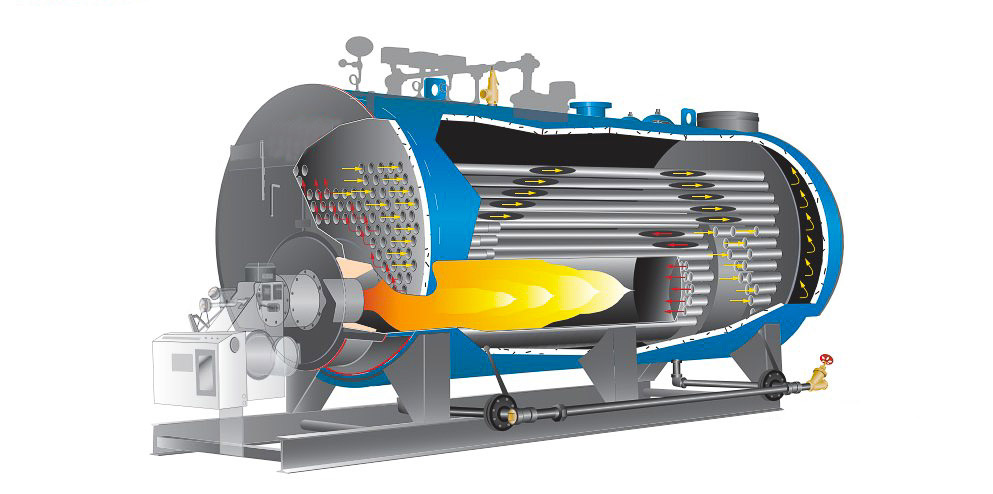

Boiler water consists of two types of inputs in the form of makeup water and recirculating water. We will consider a water tube boiler. Water will enter the tubes, which are surrounded by burning fuel. The heat from the fuel burn will transfer to water containing in the water tubes to form saturated steam. The steam will then head towards the boiler drum. Boiler drum will separate steam from the water and will direct towards superheaters to form superheated steam. Water containing in the boiler drum will get back to water tubes. Steam generated from the process is taken to its heat transfer process. Right after performing its heat transfer, steam will condense through a condenser to return back to its original state. By now, water has completed a full cycle. Condensed water will pass to water tubes once more to repeat the same process described before. The water that enters the boiler via a condensation process is referred to as recirculating water.

As the cycles continue to repeat, water quality will decrease drastically. Unless a carryover occurs, steam doesn’t carry any impurities along with it. Therefore impurity concentration in the boiler drum will increase considerably. Hence some portion of water from the boiler drum should blowdown to maintain the water quality of the cycle. Blowdown will result in inadequate water in the boiler cycle. Therefore water amount of discharged via blowdown should be replaced from an external source. This is referred to as makeup water. A proper boiler water treatment should address both recirculating and makeup water. In order to maintain boiler water standards, external treatment, as well as internal treatment, is equally important.

Common issues in boilers

Scaling

Scaling, corrosion, and carryover are the most common issues that are highly likely to hinder boiler efficiency and smooth boiler operation. Feedwater with a high concentration of Calcium and Magnesium has a tendency to create scales on water tubes. Carbon Dioxide in the feed water will transform into Carbonate ions in high temperatures. These Carbonates will link with Calcium or Magnesium ions along the way. As soon as the solubility of these combinations exceeds the remaining ions will form Calcium Carbonate and Magnesium Carbonate and will deposit in the water tubes in the form of a hard layer. These scales have very low heat transferability. Hence the fuel consumption of the overall process will become much higher.

Corrosion

Most of the boiler components are made of carbon steel. Therefore improper treatment of the water can lead to corrosion of the components. Oxygen, as well as Carbon Dioxide, can sneak into boiler feedwater along the process. These two gases will promote the corrosion of the boiler tubes and other metallic components. Oxygen acts as a cathode, while Iron in the carbon steel becomes the anode. Sufficient Oxygen in the water will promote this. Carbon Dioxide also plays a vital role in promoting corrosion. Carbon Dioxide ahs the ability to generate acidic conditions at elevated temperatures. Acidic conditions will speed up the corrosion process. Severe corrosion can lead to tube failures.

Carryover

Ideally, steam will not carry any impurities or water from the boiler drum as it separates. Still, there is always a possibility to occur this occasionally. This can lead to severe damages to superheaters, Valves, and turbine blades. The boiler drum contains water with a high level of impurities. If a carryover takes place, some portion of these highly contaminated water will carry with steam to damage the components thereafter. The main reasons for carryover are inefficient steam-water separation, overloading the drum, and foaming in the boiler drum due to oil and grease contaminations. Most of these issues can be addressed via a compact boiler water treatment program.

External Water Treatment

An internal boiler water treatment alone is not cable of treating the makeup water of the boiler. Therefore an external treatment is a must to minimize the impurities prior to internal treatment. Steps of the treatment would vary depending on the quality of the makeup water. In general External program should have the ability to remove almost all the suspended solids, Microbiological contaminants, and chlorine content in the feed water. In addition to that, the hardness of the water and the total dissolved solids should bring down to a satisfactory level.

Sedimentation

If the water source for makeup contains considerable amounts of TSS, a sedimentation process is a must. Here a coagulant (PAC or Alum) along with a flocculant (Polyelectrolyte) will flock the dispersed solids. This can increase the weight of the solids. Allowing the solids to settle to the bottom of the tank will result in TSS free water as the outcome.

Sand, Carbon Filtration

If the TSS of the water is not in a high range, a sand filtration process alone can treat the TSS. Still, makeup water with high amounts of TSS has to follow both sedimentation as well as Sand filtration. At the end of sand filtration, turbidity is excepted to reach close to 2 NTU. The activated carbon process can bring down the chlorine levels (FRC) of the water to almost zero. Also, this process has the ability to eliminate certain amounts of viruses and bacterias.

Ion exchanging process

Total dissolved solids comprise of cations such as calcium and Magnesium and anions like Silicates and chlorides. Some portion of these TDS must eliminate before feeding water to the boiler. Cation exchanger resins have the ability to remove hardness from the feed water. A cation exchanger resin consists of a negative charge that has the potential to trap Calcium and Magnesium ions to its surface. At some stage, these resins will get saturated, and a regeneration is required to remove the ions attached to the resins. Anion exchanger resins act in the opposite way to that of cation exchanger resins. These positively charged resins will trap the anions containing in the feed water. Similar to cation exchanger resins at some point of operation, a regeneration process is a must to remove anions trapped to the resin surfaces. These Resins are placed in separate vessels or in a single vessel, and feed water is fed from the top of the vessel.

Reverse Osmosis

Reverse osmosis is also can be used in treating the TDS of the feed water. Unlike resins here, the separation process takes place through a semipermeable membrane. Both cations, as well as anions, can be removed by this process. Simply pure water molecules from the feed water are allowed to pass through a membrane by applying pressure on the feed water. The efficiency of the process is much higher than that of the resin process. Industries may have resin technology or reverse osmosis to remove TDS from the feed water. In extreme cases, even both processes are possible.

Condensate Polishing

Recirculating water doesn’t require too much of external treatment. Still, recirculating water has a tendency to carry impurities from the condensation process or any other leakages. Therefore some level of treatment will always add extra protection to the process. Here the process is identical to the ion exchanger technology described earlier. Resins used in the process are temperature resistant. Any ion contamination through leakages will be eliminated through the condensate polishing process.

Boiler Water Internal Treatment

Scale Inhibition

Despite taking every measure in the External boiler water treatment, there will be some sort of scale formations. Therefore Scale inhibition process is vital in internal treatment. Phosphate/ Polymer program and chelant/dispersant program are the most common programs. The solubility of Calcium Phospate and Magnesium Phosphate is much lower than that of respective Carbonates. Hence Calcium Phospate and Magnesium Phosphate will form instead of Carbonates. Unlike Carbonates, phosphate forms a very soft sludge. This can be easily removed via the blowdown process. Adding polymer along with phosphate will generate more of a stable sludge, which will ease the removal. On the other hand, a chelant has the ability to produce complex ions of Calcium and Magnesium. These complex ions have a much higher solubility compared to the original Calcium and Magnesium ions. Hence the scaling process can be delayed by a chelant. Adding a dispersant helps to distribute these complex ions evenly.

Corrosion Control

Dissolved gases present in the feed water is the main contributor to the corrosion process. A corrosion control program needs to address this issue. A corrosion control chemical treatment consists of Sodium Sulfite or Hydrazine and an Alkalinity builder in the form of Sodium Hydroxide or an Amine. Sulfite and Hydrazine have the ability to reduce the dissolve Oxygen level by reacting with Oxygen. Very low levels of dissolved Oxygen aid to create a magnetite(Fe3O4) layer on the tubes of the boiler. This layer acts as a barrier against corrosion. Continuous addition of Sulfite or Hydrazine will result in the reduction of dissolved oxygen throughout the process. pH building agents should have the ability to maintain the pH levels between 9-11 in the boiler water. Any acidic effect from Carbon Dioxide will automatically sort out by this. Too much alkalinity beyond the limits will result in caustic corrosion. Therefore close monitoring of internal boiler water treatment is a key factor.

Antifoaming and Blowdown

Carryover is yet another concern in boiler operations. A smooth steam separation process and close monitoring of blowdown have the ability to overcome the issue in most cases. Oil and grease contamination can create foams in the drum and will promote the carryover. In such cases, an antifoaming agent can troubleshoot the same. No matter how good the treatment program, boiler water impurity concentrations will always rise as the water cycles increases. A properly managed blowdown process is the only way to control the impurity levels. Too many cycles can damage the boiler components as the concentrations exceed their limits. On the other hand, very little cycles will result in additional costs for steam generation. Therefore an optimized boiler water blowdown program with continuous monitoring is essential in generating steam effectively.

Conclusion

Boiler water treatment is one of the most important factors in a boiler operation process. Maintaining the required boiler water chemistry in feed water has to be done with great care and attention. Damages to the boiler parts and scale formation can lead to great losses to respective processes. These treatment processes might look costly, and to a certain extent, they are costly as well. Still neglecting these will only cause long term failures and hidden costs, which are much costly compared to these boiler water treatment processes.